The engineering team at Southeast Culvert has designed hundreds of underground detention systems. We partner with civil engineering design firms every day to provide them with resources and experienced guidance according to industry best practices. Our goal is to ensure that your storm drain systems are extremely cost effective, functional, and meet the standards of the municipality reviewing the project.

We regularly receive questions from design engineers about how best to design an underground detention system. A few of the more common questions are listed below.

• Should I use pipe, chambers, or another product?

• If I use metal pipe, what diameter and gauge do you recommend?

• How much cover will the underground detention need?

In this guide, we will answer these questions as well as addressing other important criteria in underground detention design.

As always, if you need some design guidance for an underground detention, water quality treatment device, or retention/infiltration system, let us know.

We usually return proposal requests within a day.

Step 1: How much depth do you have to work with?

The allowable vertical space for your underground detention system is one of the most important considerations for what product will work in the application. You have to ensure that the system will have an appropriate cover height to function structurally.

If you have a rough grading plan and your detention outlet pipe elevation, you can calculate the maximum depth (finished elevation to invert out) at the outlet location. Then you will check the edges of the detention’s allowable footprint to see if the finished grade increases or decreases significantly.

Use the shallowest depth you find as your initial allowable vertical space. You can probably manipulate the detention system’s shape and footprint later to increase that vertical space, but this depth is a good starting point for your design.

Step 2: What underground detention product will work in this space?

Every detention product has a minimum allowable cover to allow vehicular traffic loading on the finished system as well as construction loading guidelines. The construction loading minimum cover will always be more than the minimum allowable cover for traffic loading.

Start off your design assuming a minimum cover of 3’ over the detention system. That minimum cover will allow some medium construction loads on both pipe and chambers systems. This guideline does not cover all construction loads and you will need to double check the requirements of the product you specify against the equipment required during construction, but it is a good place to start.

Subtract 3’ from the vertical depth you came up with in step 1. That depth is the allowable vertical dimension of the detention system.

*Note: If the allowable detention footprint and depth based on these guidelines does not allow you to provide the required volume, then you can reduce the cover over the system. That will allow you to expand the system footprint and increase the size of the pipe or chamber system you are using. The minimum cover for either product is in the range of 12-24” to the bottom of flexible pavement or to the top of rigid pavement.

Designing the system closer to the minimum cover requirements will necessitate more coordination with the contractor to make sure that the construction loading requirements are maintained through construction.

Step 3: Choose the most cost effective detention product

Now that you have the maximum vertical dimension of your detention product, you can look at the different available options and do some value engineering.

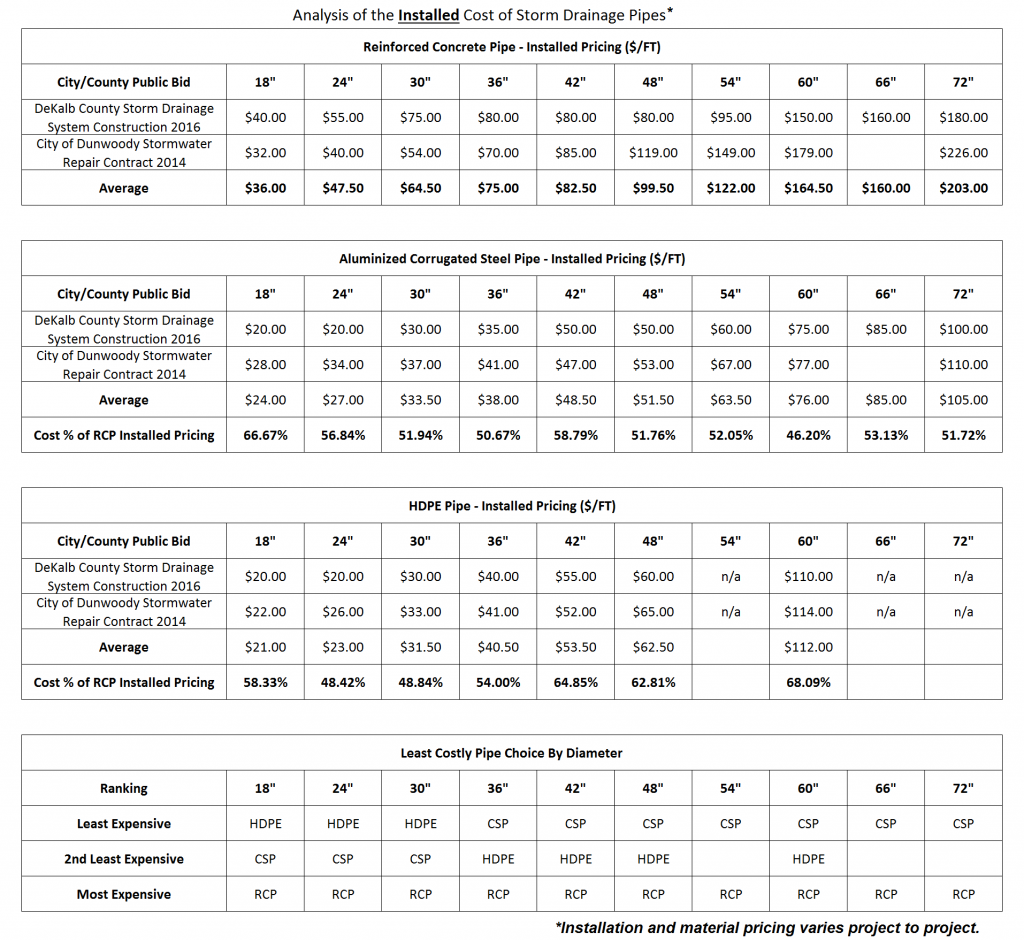

Generally, the least expensive detention system product on the market is corrugated steel pipe. Designing with the product is fairly easy because the minimum and maximum covers on the product allow you a wider range of design than almost any product.

For instance, the minimum allowable cover on 72” diameter steel pipe for H-20 highway loading is 12” to the bottom of flexible pavement and the maximum cover is 52’. No other product has that range of cover heights.

Corrugated steel pipe is available in a wide range of diameters from 12” to 144”, so you can fine tune your design to maximize your storage volume in the smallest footprint.

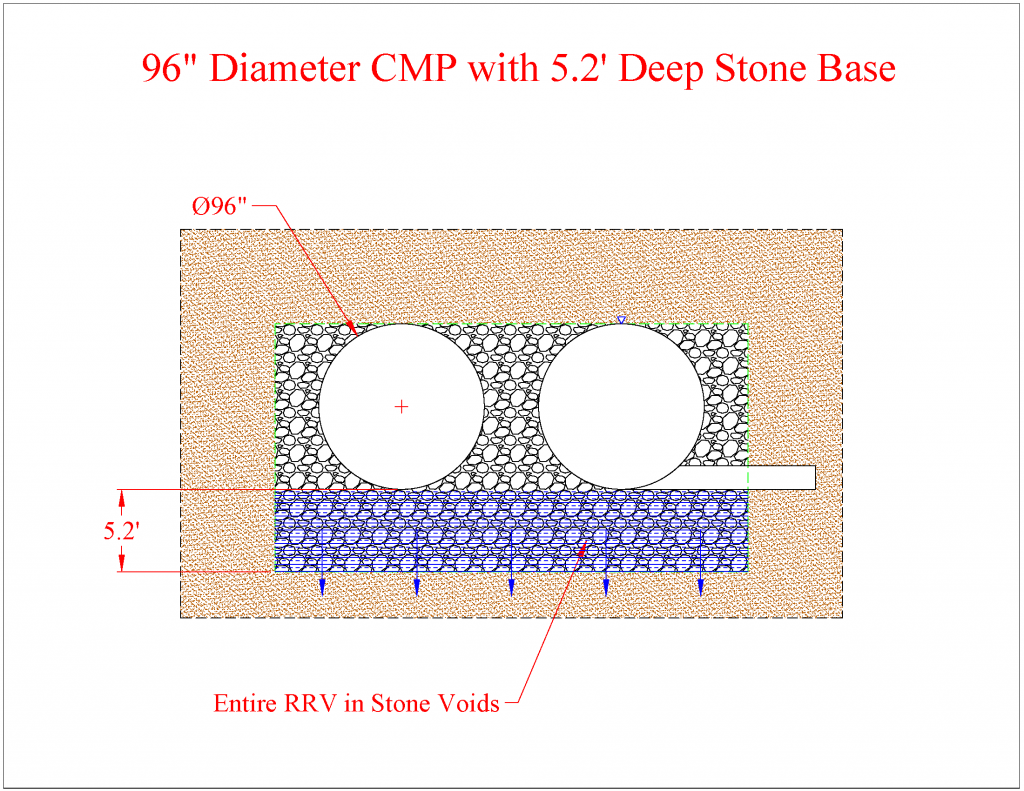

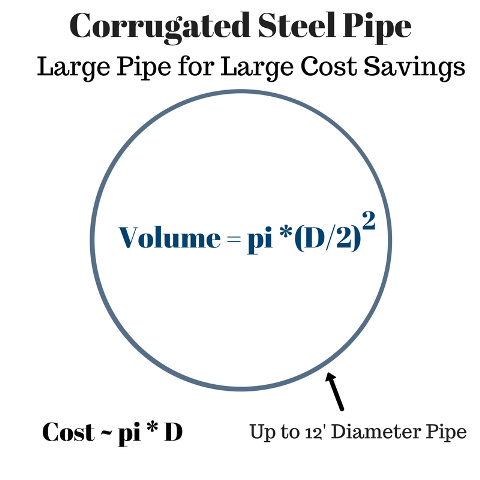

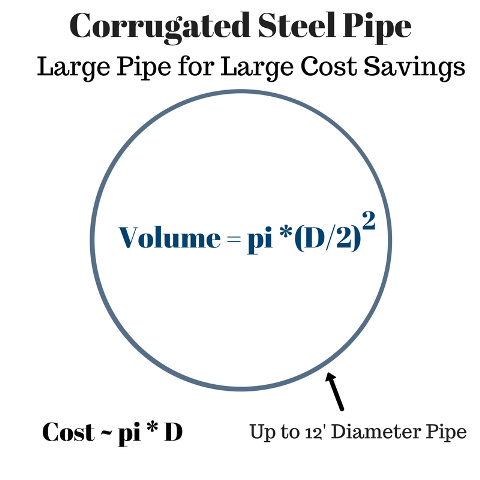

For corrugated steel pipe detention systems, choosing the largest diameter allowable leads to a cheaper price for the installed system. The reason for this characteristic of the product is that the amount of steel in the pipe increases according to the perimeter of the pipe (pi)*Diameter while the volume stored in the pipe increases according to the cross sectional area of the pipe (pi)* (Diameter/2)2.

For example, the weight of 48” diameter 16 gauge corrugated steel pipe is 38.6 lbs/ft and the cross sectional area is about 12.5 sqft. The weight of 84” 14 gauge corrugated steel pipe is 82.2 lbs and the cross sectional area is about 38.5 sqft. The amount of steel in 48” diameter pipe is about 3 lbs/sqft while the amount of steel in 84” pipe is about 2.15 lbs/sqft.

There would be approximately 30% less steel required per cubic foot of storage for an 84” diameter steel pipe detention system compared to a 48” diameter system. The system footprint would also be smaller.

If the allowable depth does not allow large diameter steel pipe, then you could look at getting budget pricing on a CSP system compared to a chamber product style system.

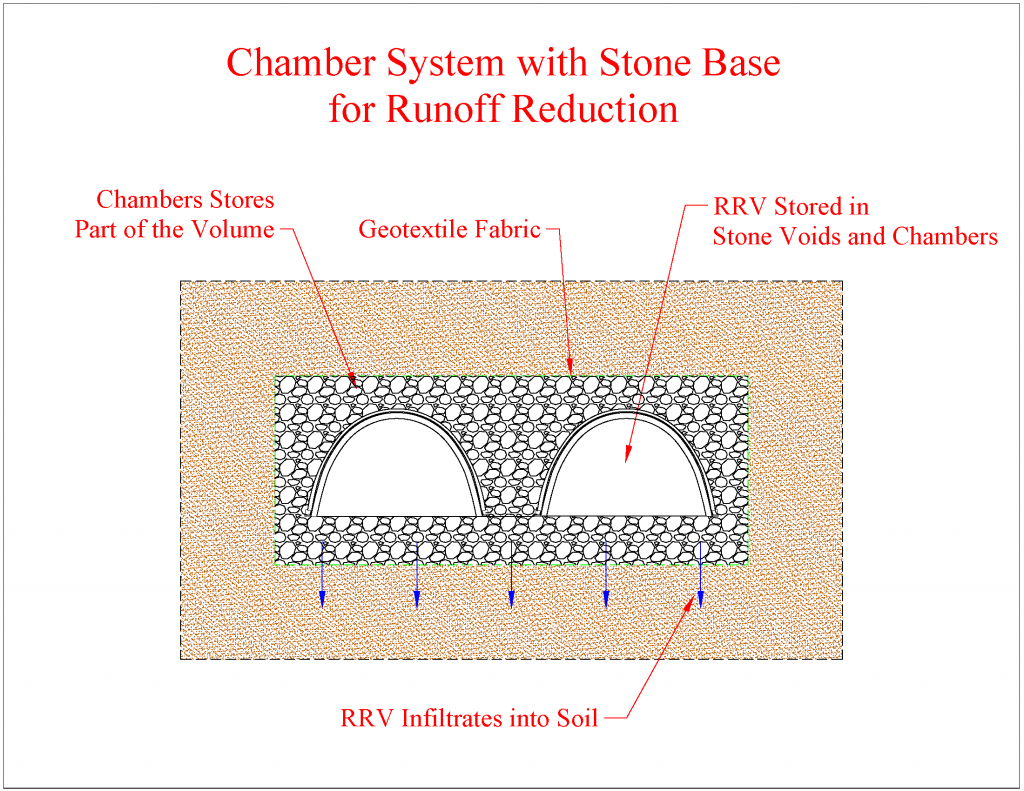

The general rule for when the cost of a chamber system is competitive with a metal pipe underground system is when the allowable pipe diameter is 54” (4.5’) or less. If your project only has room for a system around this size, then you should get a budget proposal for a metal pipe detention system and a chamber system and compare the costs and system footprints. It is important to consider the amount of stone required for both systems in addition to the material cost.

Should the corrugated steel pipe detention be perforated or solid?

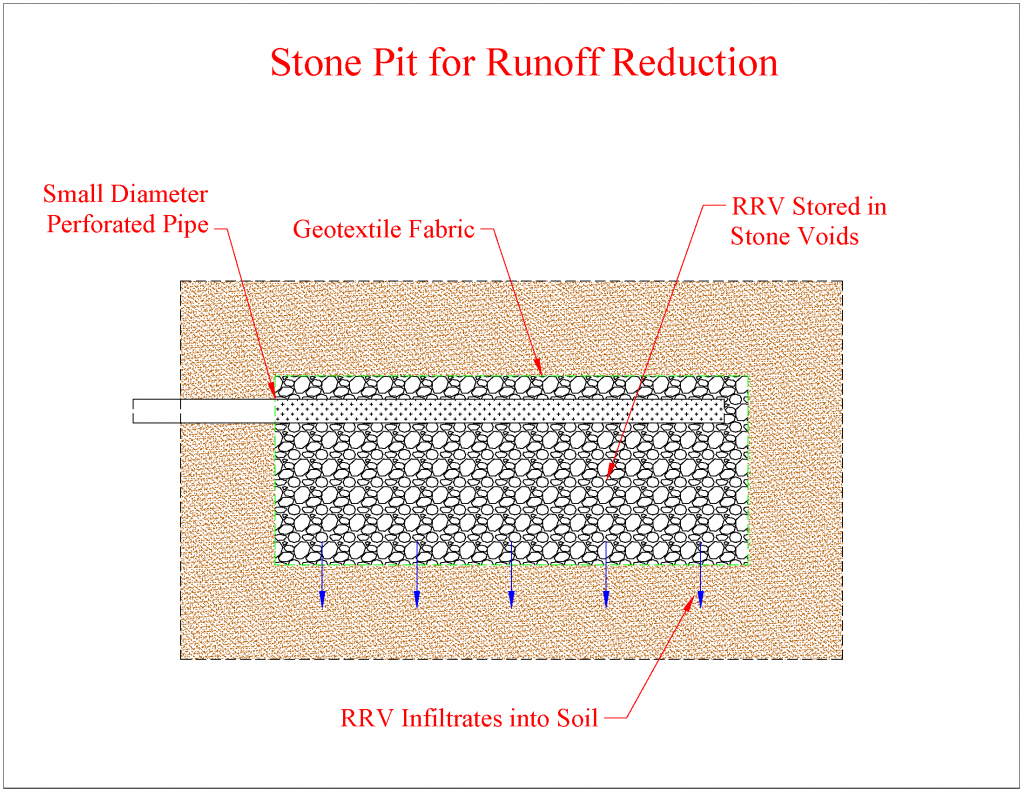

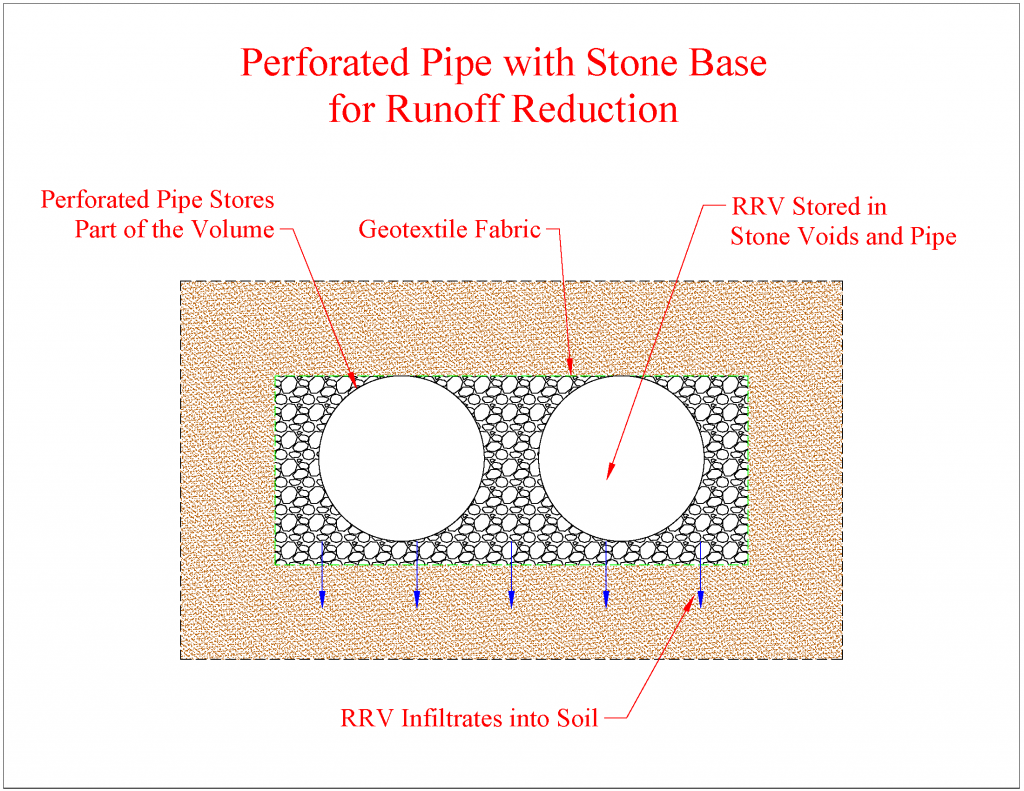

Designing corrugated steel pipe detentions fully perforated and surrounded in a stone envelope has become very common since municipalities have begun requiring some level of retention and infiltration of storm water on new projects.

Perforating the detention system has several design benefits:

1. The system size is significantly reduced

2. The system is backfilled in stone, which speeds up the installation of the detention

3. The new Georgia Stormwater manual gives full water quality treatment credit if you can show the first 1” of rain being retained and infiltrated.

4. A perforated steel pipe detention typically requires significantly less stone than a comparable chamber system.

What is the least expensive diameter of corrugated steel pipe for a detention system?

As a general rule, the larger diameter you use for an underground detention system, the cheaper it becomes per cubic foot of storage. There are some diameters that are cheaper than others because they are the largest diameter before the pipe has to be made with a heavier gauge of steel.

The least expensive per cubic foot pipe diameters are: 60”, 84”, 108”, and 144”.

Those sizes are based on the industry standard gauging guidelines, but some municipalities have heavy gauge requirements. If you have a question about a system you are designing, you can contact our engineering team. We can tell you the best practices for the specific municipality reviewing your project.

As always, if you want to send your project to our engineering team then we will put together a detention proposal that includes stage storage tables, a layout detail, and budget pricing for the system.

We typically return a proposal within a day of getting a request.

Additional Tips

Use bulkheads in lieu of manifolds

Metal pipe detention systems consist of individual runs of pipe joined together with a manifold on the end. The typical configuration for a detention has both ends of the system joined into a manifold, but we recommend leaving the upstream end of the system un-joined and putting bulkheads on the pipe.

The fabricated tees on a manifold a significantly more expensive than bulkhead caps, so using bulkheads reduces the system cost. It also reduces the number of band connections and speeds up the installation of the system.

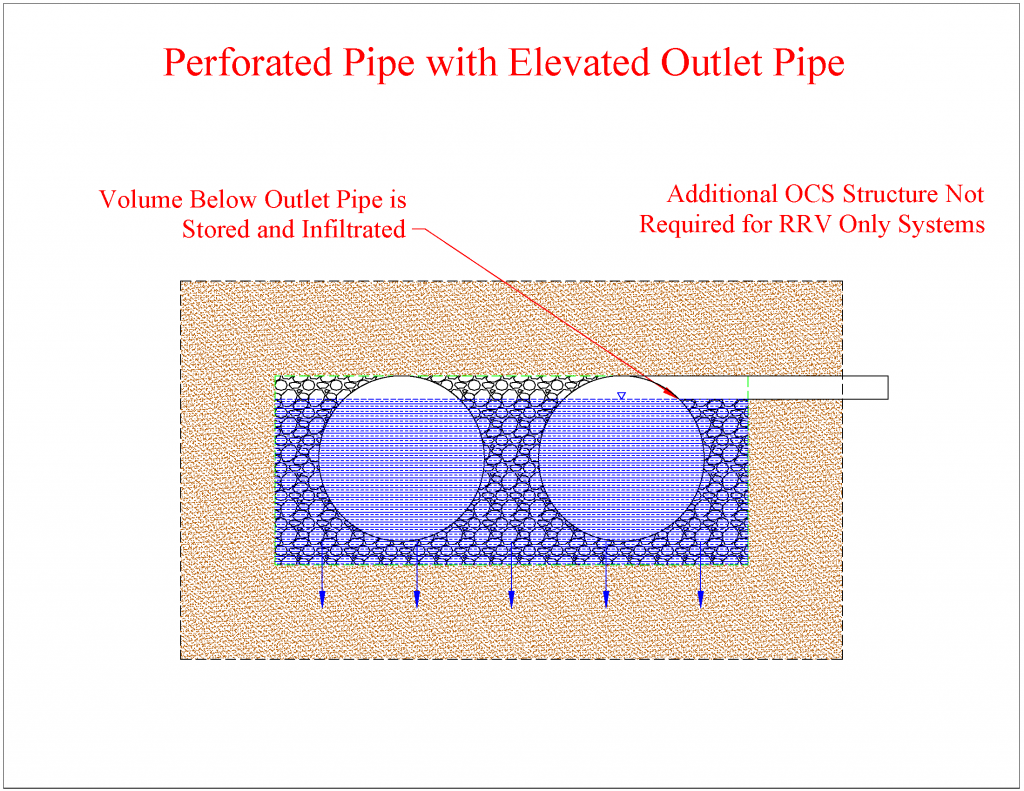

Use a smaller outlet pipe

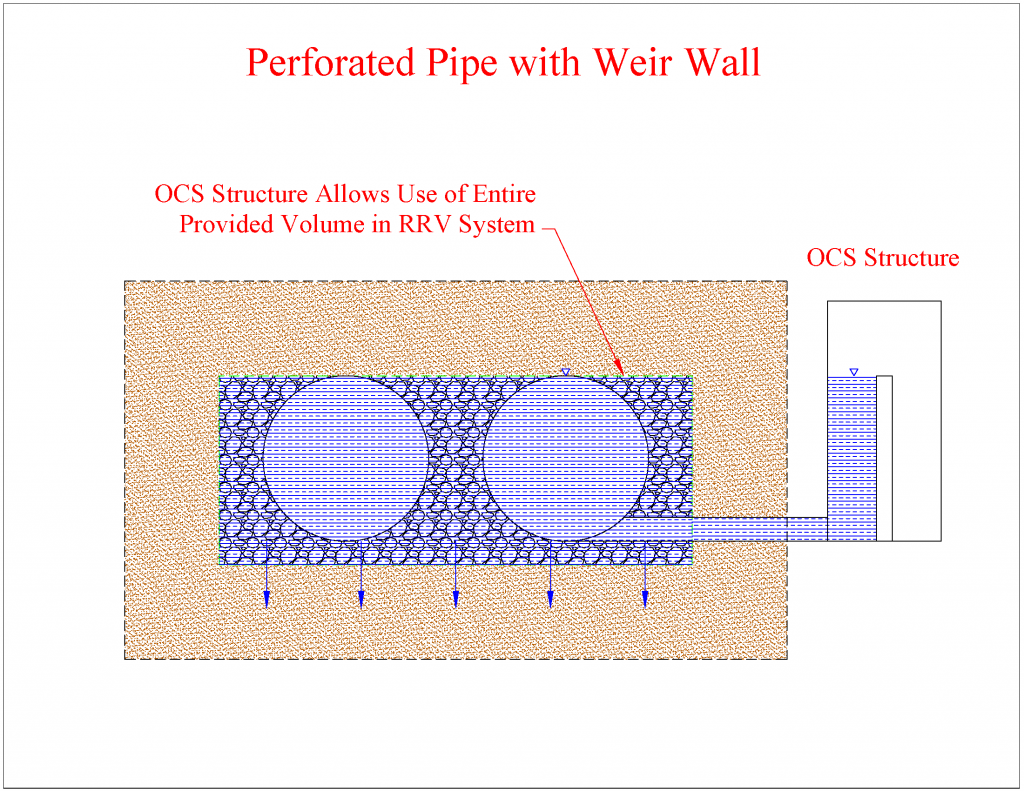

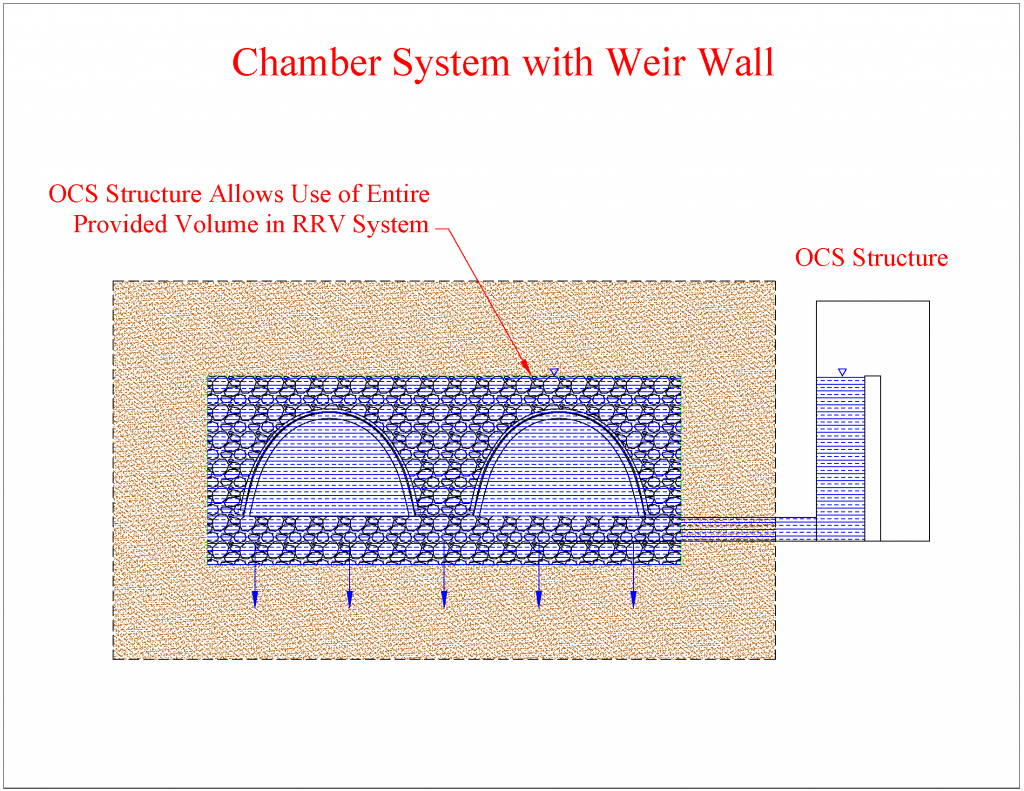

One mistake we see a lot on underground detention designs is to tie the detention pipe itself directly into the outlet control structure on a system. For larger diameter pipe detentions, that configuration leads to large precast OCS structures. Reducing the outlet pipe to 36” pipe or something similar can reduce the cost of the OCS structure by thousands of dollars.

Design the OCS weir plate inside the detention pipe

A custom weir plate can be fabricated inside the pipe to eliminate the OCS structure. Designing the system with an internal weir plate can reduce the overall cost of detention, especially for large diameter systems where the required OCS box would be expensive.