STUDIOS AND MOVIE PRODUCTION SETS

CUSTOM FABRICATIONS

STUDIOS AND MOVIE PRODUCTION SETS

CUSTOM FABRICATIONS

Structural Plate is an effective solution for job sites requiring culverts, stream enclosures, underpass or overpass. The unique curved plate components allow ease of shipment and onsite storage, and once bolted together can provide an open clear span across protected waters. Multiple configurations are available so please contact us to assist you in matching the best solution for your job site requirements.

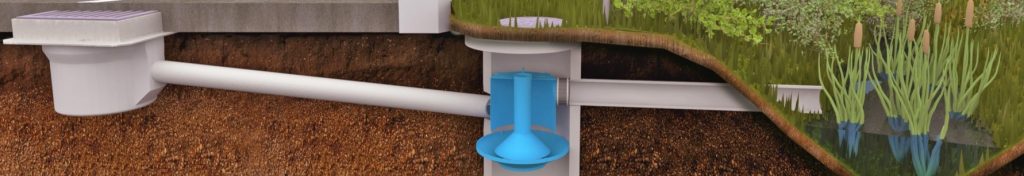

Nationwide, non-point source pollution control measures and innovative flood prevention techniques play an increasingly critical role in community development and economic growth. Increased urbanization and regulations have created complex challenges for managing the quality of storm-water runoff.

Southeast Culvert can provide product solutions for filtration and suspended solids removal that your project demands. Teaming up with Hydro International as their exclusive sales representative in Georgia, we can provide clients with high performance, low-maintenance storm-water management technologies.

Detention Systems manufactured with Corrugated Steel Pipe exceed all performance criteria. CSP Systems are economical, adaptive, structurally sound and durable. No other method for containing storm water runoff can achieve the results obtainable with Corrugated Steel Pipe Detention Systems. Southeast Culvert, Inc. can assist with the design and layout of your next detention system.

Foundation and Bedding

Prior to placing any bedding the foundation should be uniform and stable. Any unsuitable foundation material shall be removed. At a minimum 4 inches of a well-graded granular material shall be placed as the bedding (#57 stone or similar if there is no suitable on site material).

Backfill

The backfill material shall be an A1, A2 or A3 granular fill per AASHTO M-145, some local soils may meet the material requirements but should be approved by the engineer or geotechnical engineer. The material shall be placed in equal lifts and compacted to minimum 90% AASHTO T99 standard proctor density. The backfill should be carefully placed and compacted under and around the pipe haunches.

The backfill should be placed evenly on both sides of the structure and advanced along the pipe length at the same rate to avoid differential loading. At a minimum, larger, multiple barrels and more critical structures should have stone or a uniform graded material, not larger than ½ inch in size, placed for the initial 1.5 to 2 feet up the pipe elevation or to the spring-line elevation of the pipe. A separation geotextile fabric is to be placed above and below this initial fill material.

Minimum Cover

Cover should be placed to the proper elevation as outlined in the plans. Construction loadings need to be determined based on the type of equipment planned to be used during construction.

Minimum cover for construction equipment is different than standard vehicle loadings and should be carefully assessed prior to placing any equipment on the structure. Follow the chart as outlined in the NCSPA

Installation Guidelines:

|

Pipe Span, in

|

18 – 50 kips

|

50 – 75 kips

|

75 – 110 kips

|

110 – 150 kips

|

|

12-42

|

2.5 ft

|

2.5 ft

|

3 ft

|

3 ft

|

|

48-72

|

3 ft

|

3 ft

|

3.5 ft

|

4 ft

|

|

78-120

|

3 ft

|

3.5 ft

|

4 ft

|

4 ft

|

|

126-144

|

3.5 ft

|

4 ft

|

4.5 ft

|

4.5 ft

|

The ends of corrugated pipes can be simply installed as square ends or they can be beveled or skewed to match the embankment slope. When specified for hydraulic considerations, metal Flared End Sections (FES), Safety Flared End Sections (SFES), or concrete headwalls can be supplied. Common sizes are in stock and can be prepared for immediate shipment. Let us help you fulfill your next project’s needs.

Southeast Culvert provides pipes of diameter 54″ to 144″ in a 5″ x 1″ or 3″ x 1 ” corrugation profile so that the pipe maintains structural integrity. These pipes are usually manufactured in 14 gage or heavier to ensure durability of the c.m.p.

Heavier gages allow the pipe to maintain deeper heights of cover.

Gage and corrugation should be determined from height of cover charts published by ASTM, AASHTO, or local DOT’s. All of Southeast Culvert‘s corrugated steel pipe meets or exceeds the steel pipe specifications AASHTO M36 and ASTM A760.

COATING SPECIFICATIONS:

Plain Galvanized Pipe (Zinc Coated) Aluminized Steel Type 2 (ALT2)

–AASHTO M218 -AASHTO M274

–ASTM A929 –ASTM A929

CORRUGATED METAL PIPE

Southeast Culvert manufactures the full range of corrugated metal pipe diameters 12” to 144”. One can select from the full range of possible coatings – galvanized, aluminized, or polymer – and from the full range of possible corrugation profiles – 2-2/3 x ½, 3 x 1, 5 x 1, ¾ x ¾ (spiral rib). We also offer pure aluminum corrugated pipe.

SPECIFICATIONS

All Southeast Culvert’s corrugated metal pipe meets or exceeds specifications ASTM A760 and AASHTO M36.

The following specifications are met according to coating requirements.

Plain Galvanized Pipe (Zinc Coated)

Aluminized Steel Type 2 (ALT2)

AASHTO M218-AASHTO M274

ASTM A929-ASTM A929

ASTM A849

ASTM A849-AASHTO M218

Max Flow spiral rib pipe combines all of the most essential elements of a storm drain system: hydraulic efficiency, structural integrity, durability, and economics. Max Flow is one product that should be included in all storm drain projects.

Hydraulics

Max Flow Spiral Rib Pipe is hydraulically equivalent to other smooth interior pipe products. The designer can now perform one hydraulic analysis and specify competitive products. Hydraulic tests confirm that the Mannings is 0.012 for Max Flow.

Long pipe joints, prefabricated junctions and a smooth interior constitutes Max Flow Spiral Rib Pipe as the hydraulically premier product available.

Economy

Max Flow Spiral Rib Pipe is a corrugated metal pipe product. All of the advantages attributable to metal pipe applies to Max Flow.

A comparison of the pipe’s physical qualities are the first advantages usually distinguished between the competing products. The standard joint is twenty feet in length compared to eight feet for Reinforced Concrete Pipe. The standard joint weighs approximately 10% to 20% than that of the same size RCP.

Typically the actual material cost is lower than that of RCP or plastic pipe. If the prefabricated fittings for manholes, inlets, outlets and elbows are all factored in the cost savings for the material can be substantial.

NFlow HDPE (Plastic Pipe)

HDPE has built its reputation on durability, performance and economics. The reliability of HDPE has made it the product of choice by many contractors, engineers and county/state agencies. Southeast Culvert manufactures HDPE pipe diameters 12” to 60” with the latest technology and with engineered profiles that maximize its structural load capabilities.

In the past two decades the face of the storm drainage industry has drastically changed. Materials engineering has provided a pipe product with the highest strength to weight ratio available among drainage products. HDPE has built its reputation on durability, performance and economics. The reliability of HDPE has made it the product of choice by many contractors, engineers and county/state agencies. Southeast Culvert, Inc. produces HDPE in diameters from 12 – 60 with the latest technology available.

Specialty Fabrications

Southeast Culvert can provide a variety of specialty fabrications in HDPE. These structures are advantageous for complex systems such as roof drainage and underground detention manifolds. HDPE can also be fabricated into drop inlets for yard or sports field drainage problems. Each inlet is supplied with a removable grate for maintenance purposes. Fabrications can be made to order. Contact SEC for more information.

Durability

HDPE is a tough material that can withstand handling and installation processes. It is the most chemically inert drainage product available. NFLOW pipe is effective in a PH range from 2 to 14. No other drainage product can consistently perform in such a large PH range.

Abrasion can be the most destructive force that drainage pipes will endure, specifically the invert of the pipe. Abrasion is caused by bedload that is carried by high velocities. HDPE is highly resistant to abrasive wear due to its physical makeup and ductility.

The resistivity of soils does not effect the performance of HDPE. NFLOW pipe has an excellent record of success in both alkali and acid installations, and it exceeds expectations in harsh environments.

For additional information on storage, handling, and installation of HDPE pipe, please refer to Plastic Pipe Institute’s handbook found below.

Southeast Culvert chamber products can be used for both underground detention and reduced runoff retention systems. The chambers are manufactured according to the requirements of ASTM F2418 and can support H-20 vehicular loads if installed according to manufacturer recommendations.

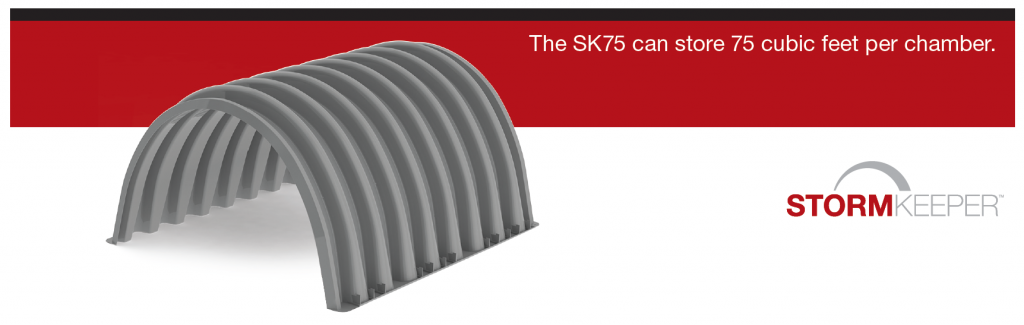

The Stormkeeper SK75 chamber is a 1 for 1 equivalent to the leading brand’s 30″ tall chamber. The SK75 model is most useful in very shallow applications.

SK75 Chamber Cross Section 30in Chamber

SEC StormKeeper SK75 Chambers -Installation_guide

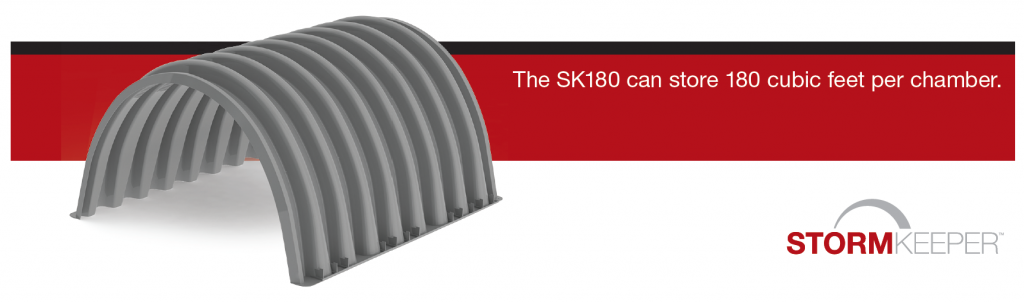

The Stormkeeper SK180 chamber is a 1 for 1 equivalent to the leading brand’s 45″ tall chamber. The SK180 model is larger than the SK75 model, so it holds more volume in a smaller footprint compared to the SK75.

SK180 Chamber Cross Section 45in Chamber

SEC StormKeeper SK180 Chambers Installation_guide

Please contact our engineering department for design recommendations for chamber detention systems and system pricing.