100,000+ Cubic Foot Detention System for Watermark Condos

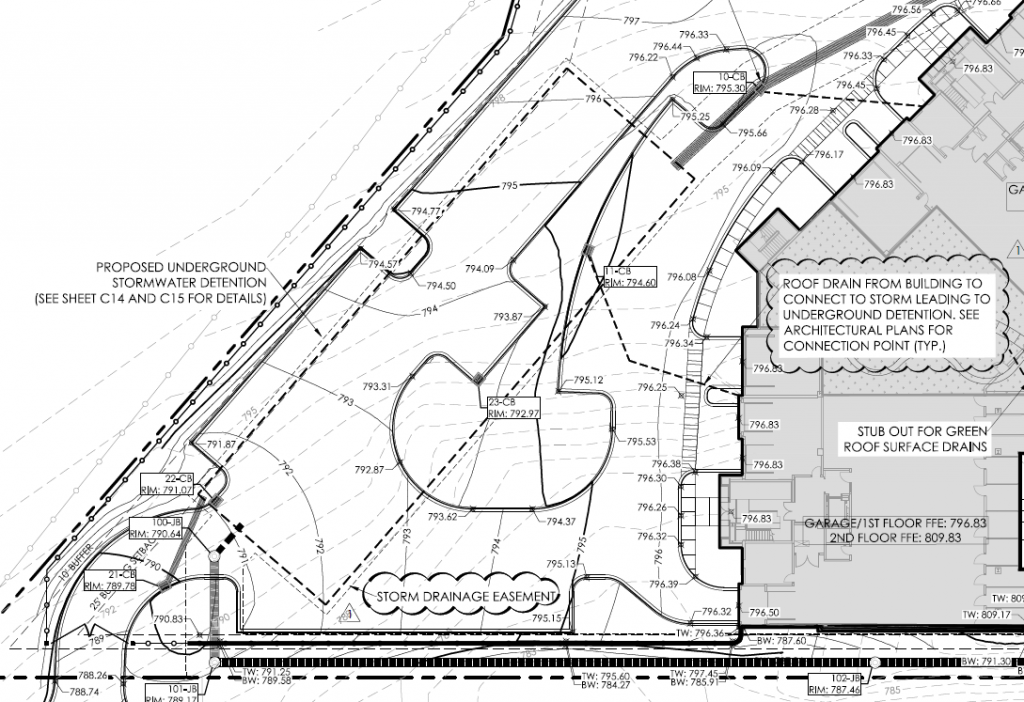

The Watermark Luxury Condo development in Cornelius, North Carolina is another example of how early collaboration between the project engineer, developer, and drainage manufacturer can reduce a project’s cost.

Initially designed with a concrete vault for the underground detention system and RCP for the stormdrain pipe, the developer JMR Construction approached the engineering team at Southeast Culvert for a value engineering proposal.

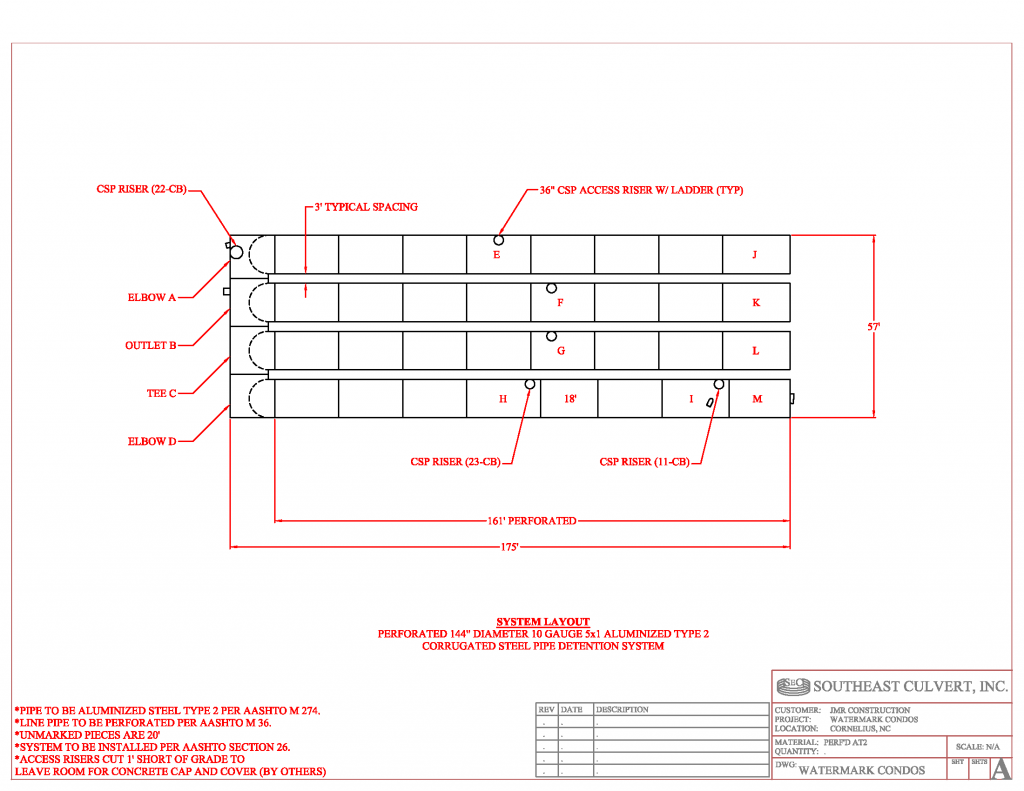

After coordinating with the project engineer Henson Foley, the detention system was redesigned as a perforated 144 inch diameter aluminized type 2 corrugated steel pipe system providing more than 100,000 ft3 of storage.

Most of the stormdrain pipe was changed to spiral rib corrugated steel pipe, which has the same hydraulic capacity as RCP or HDPE pipe (Manning’s n = 0.012). Spiral rib CMP is one of the material options we recommend when allowing multiple drainage pipe material options.

Southeast Culvert Manufactures and Delivers the System

144” diameter CMP is the largest pipe that Southeast Culvert produces. Pipe that large comes with a lot of challenges during production and delivery, but the entire system was delivered on schedule.

JMR Construction Installs the System

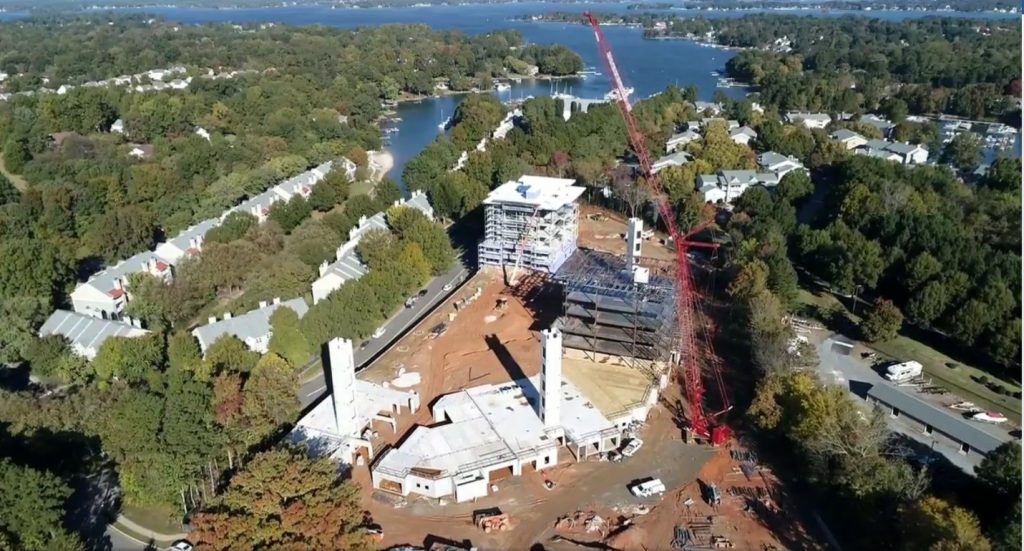

The installation of the detention system was documented via drone. The footage and pictures were shared by JMR Construction for use in this article.

Recently, Tindall Corporation posted a drone video of the progress that has been made on the development on their LinkedIn page. If you follow the link to their post, then you can view the video.

Interested in Value Engineering?

If you are interested in value engineering the drainage system of a project, contact our engineering department..

We can provide budget pricing, submittals, drawings, and other assistance to make sure your project goes smoothly.